A robust and professional CMMS – EAM that will make your maintenance management job easier than ever. Implement your MP preventive maintenance program right now.

Desktop App

Maintenance Management

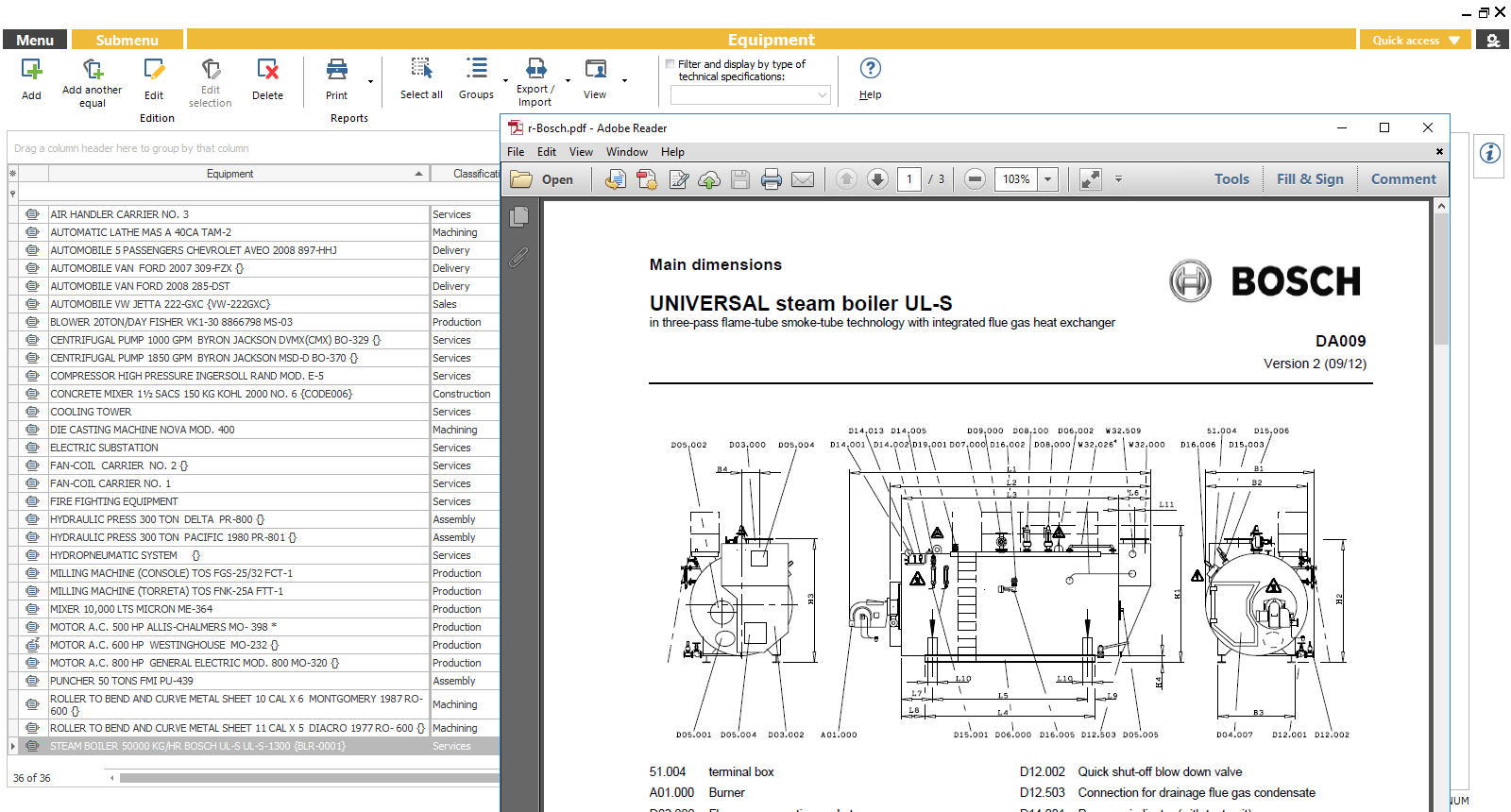

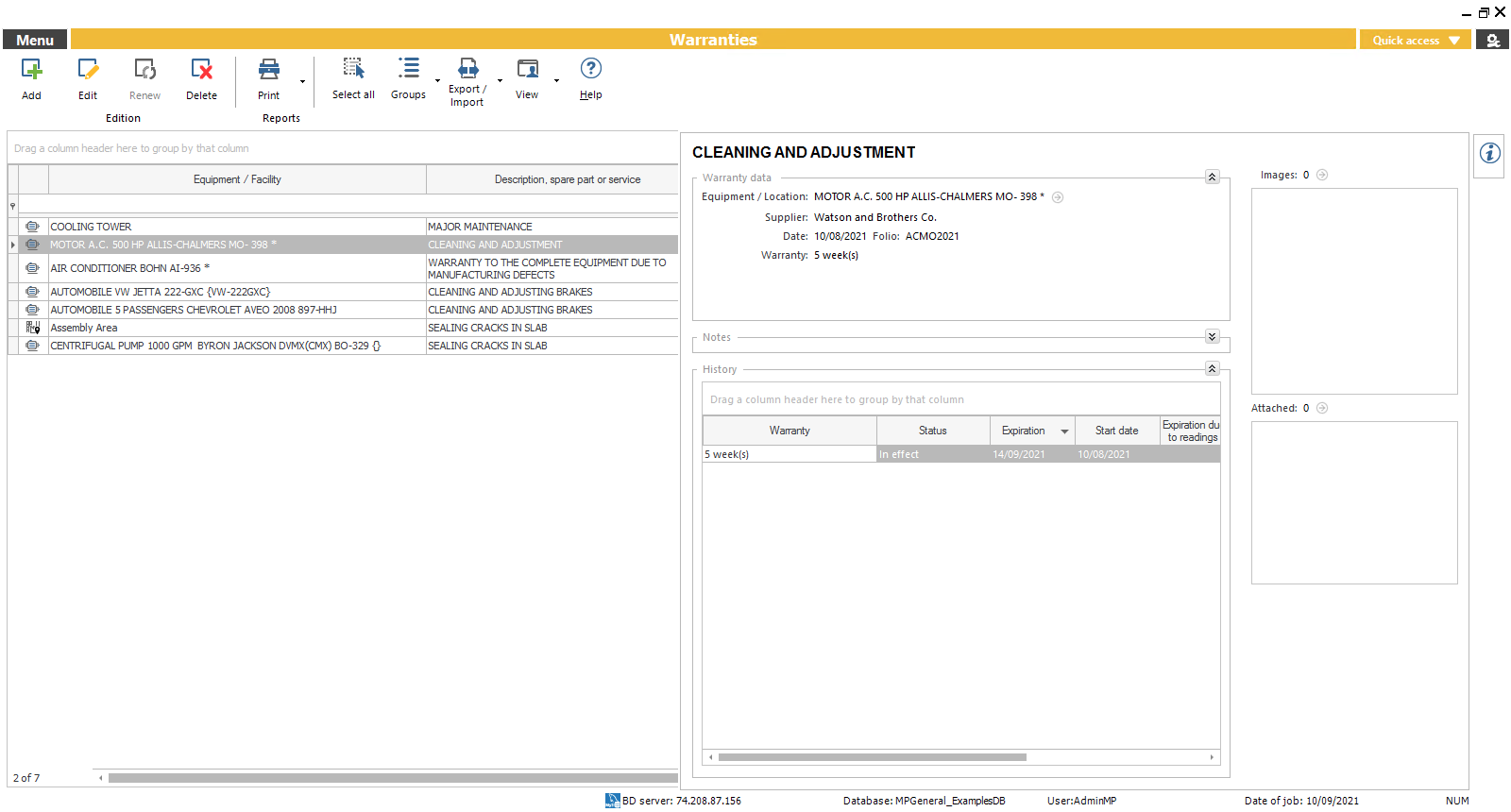

Complete documentation of the company’s assets.

Documents in the MP all the information about your assets such as technical data, maintenance plans, spare parts, supplier data, images, plans, diagrams, videos, location, warranties, etc …

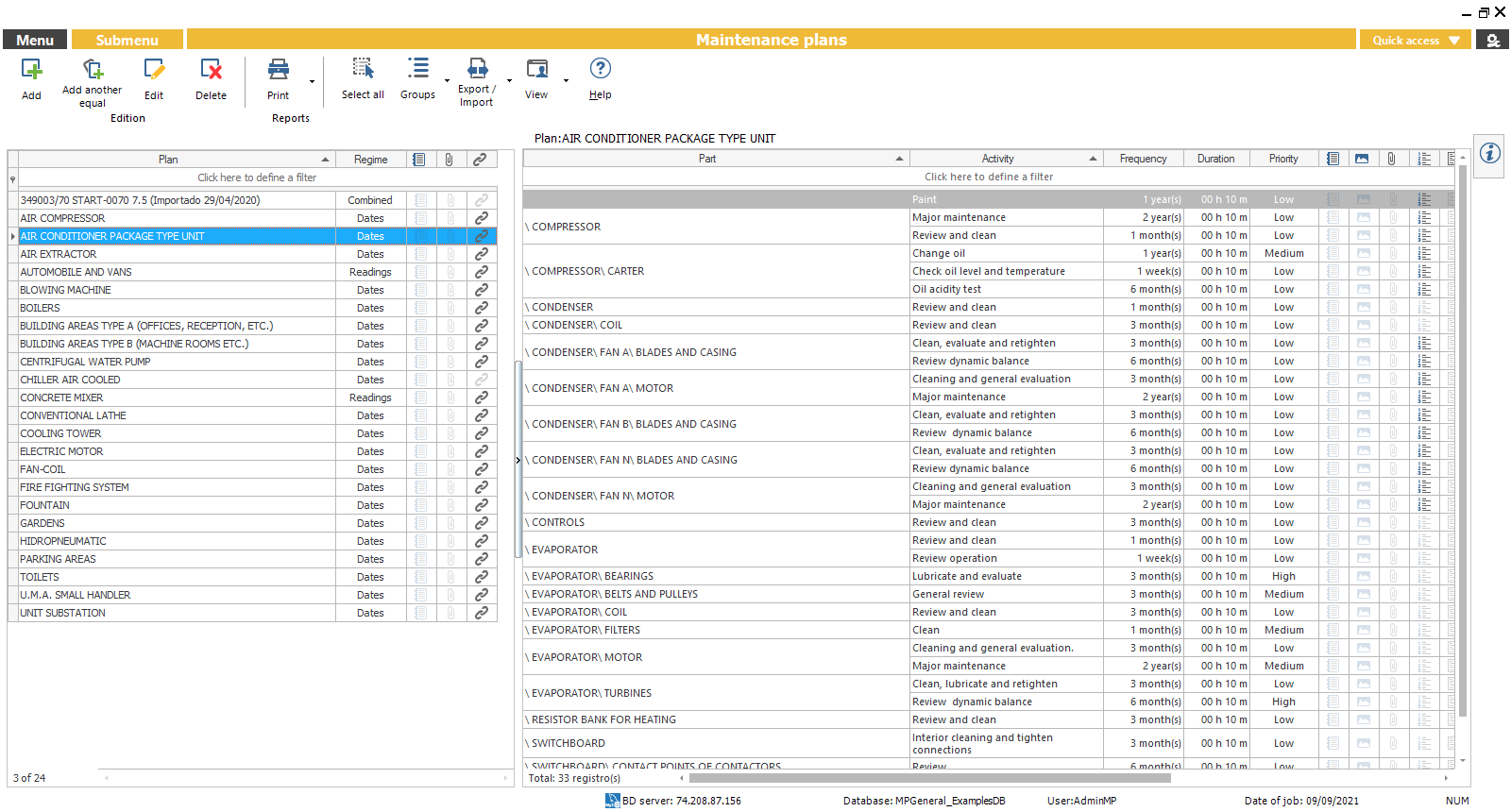

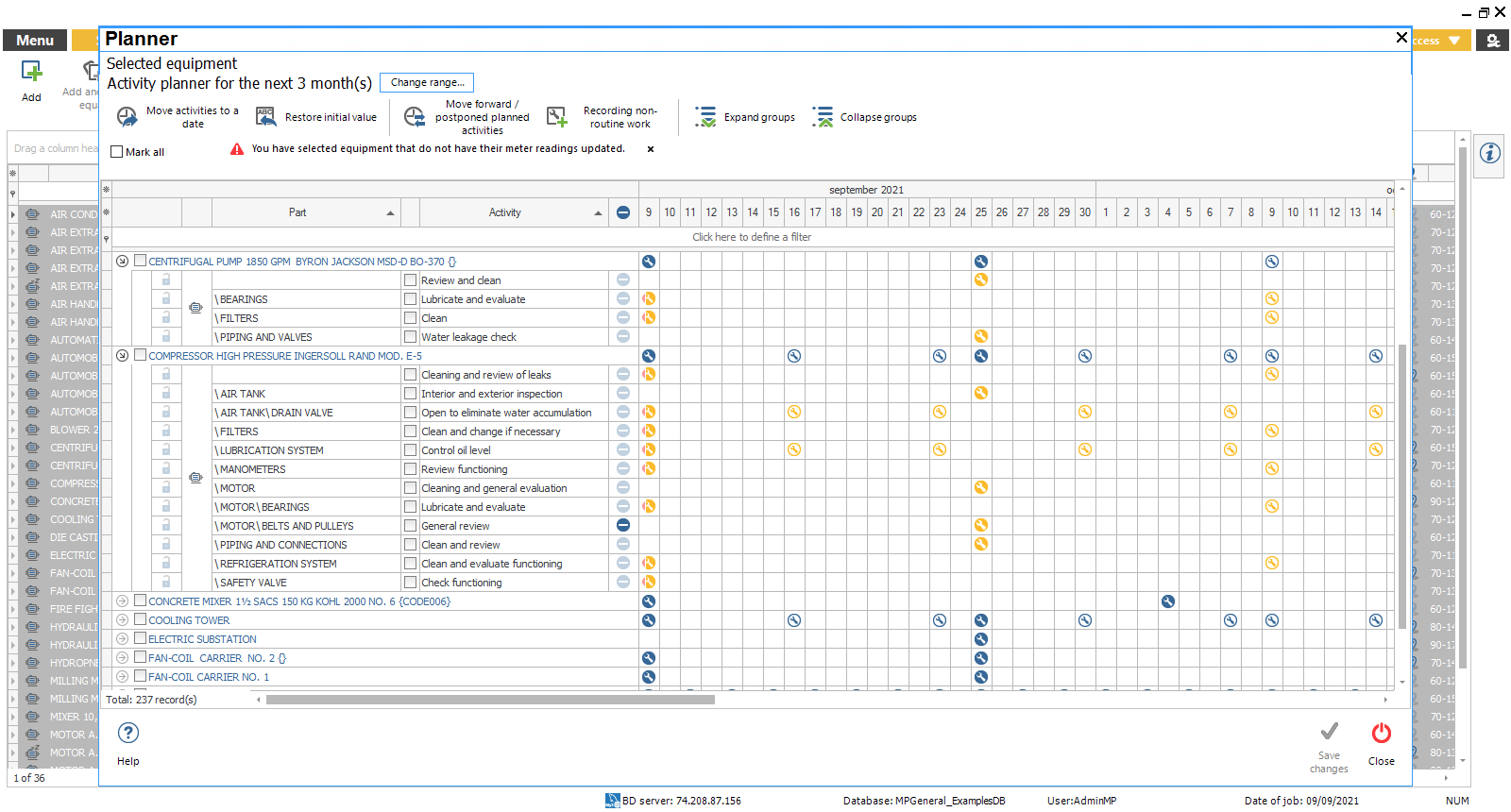

Maintenance plans and schedules

The maintenance calendars graphically show the maintenance work schedule, indicating the dates when such work must be carried out. Every time the user reports to the MP about a routine work performed, the MP reschedules the next date when it must be done again, automatically adjusting the maintenance schedules.

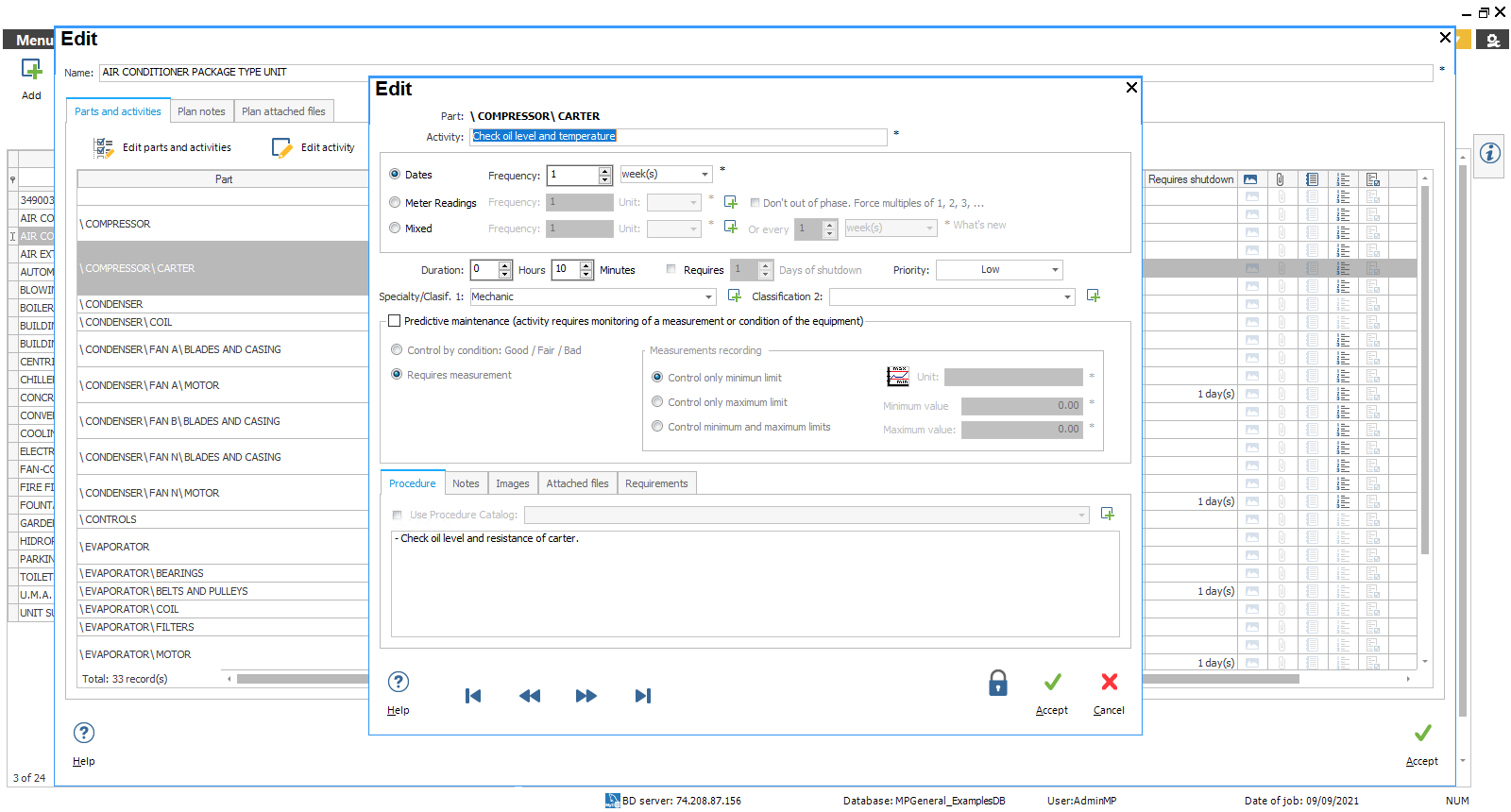

Maintenance activities controlled by dates, readings, or whichever comes first

In date-based maintenance activities, the frequency with which the activity must be performed is set based on the elapsed time. (Example, daily, every week, every 15 days, every 3 months, every 2 years, etc.)

In readings-based maintenance activities, the frequency with which the activity must be performed is established based on the use of the equipment. (Example, kilometers traveled, hours of use, units produced, number of ignitions, cycles, etc.)

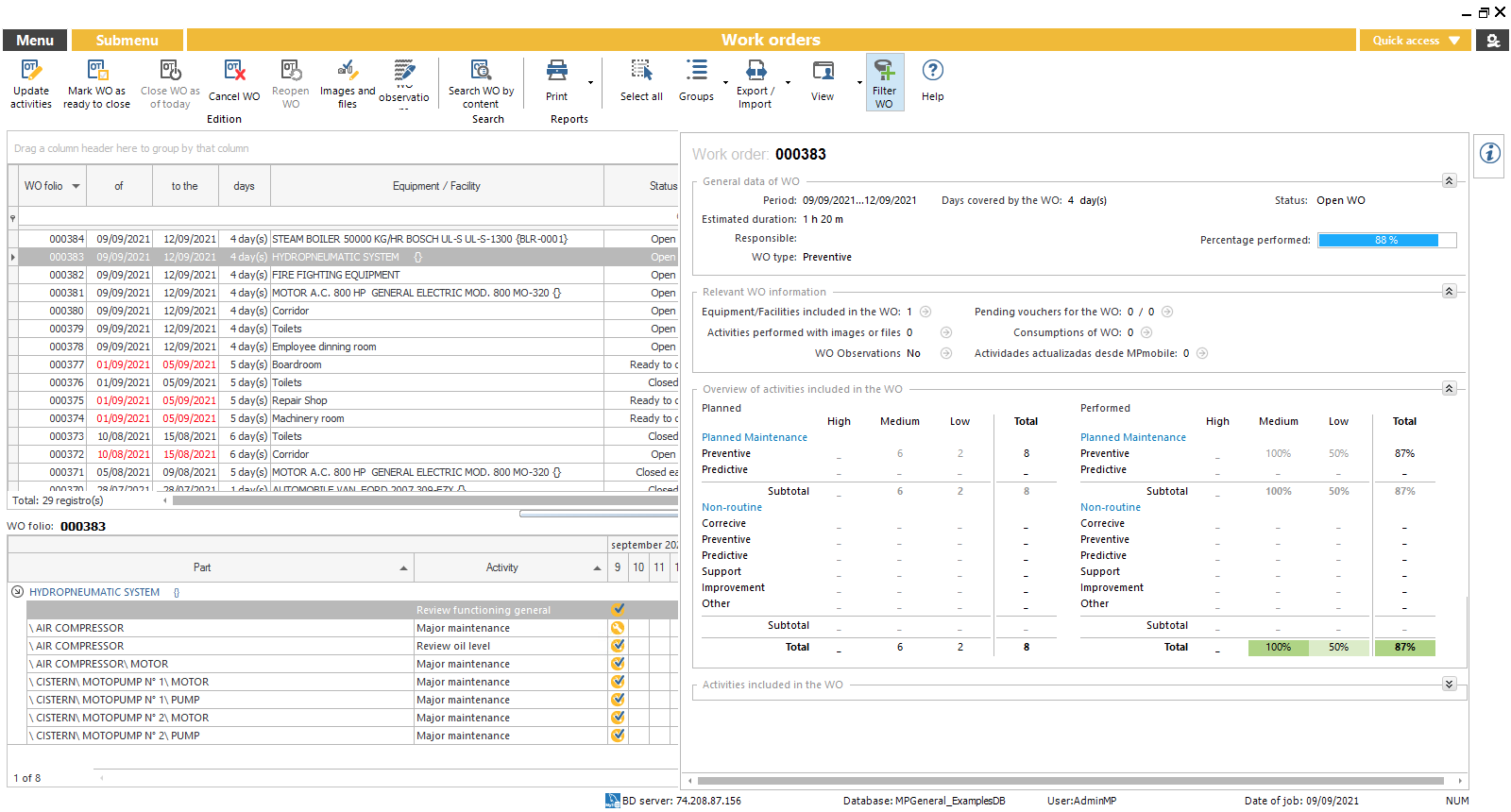

Generation, administration and follow-up of work orders

An important improvement in version 10 can be found in the work order generation process, which is now much more versatile, intuitive and easy, with different routes or paths from which you can generate your work orders.

Once your work orders have been generated, in this module you will be able to consult, print, update the work carried out and close your completed work orders.

In addition, you can assign the person in charge and register the spare parts, consumables and external services that you have used.

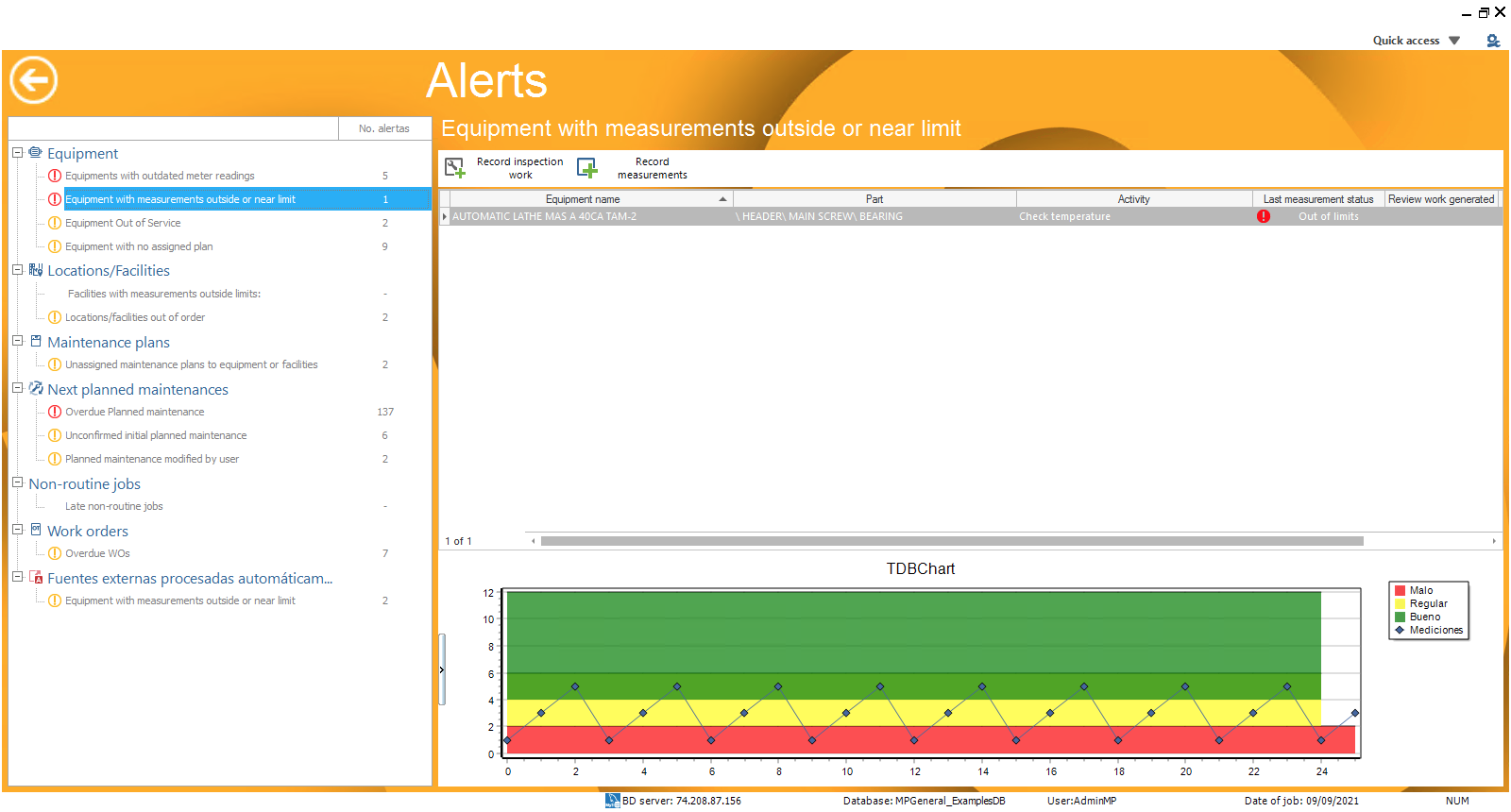

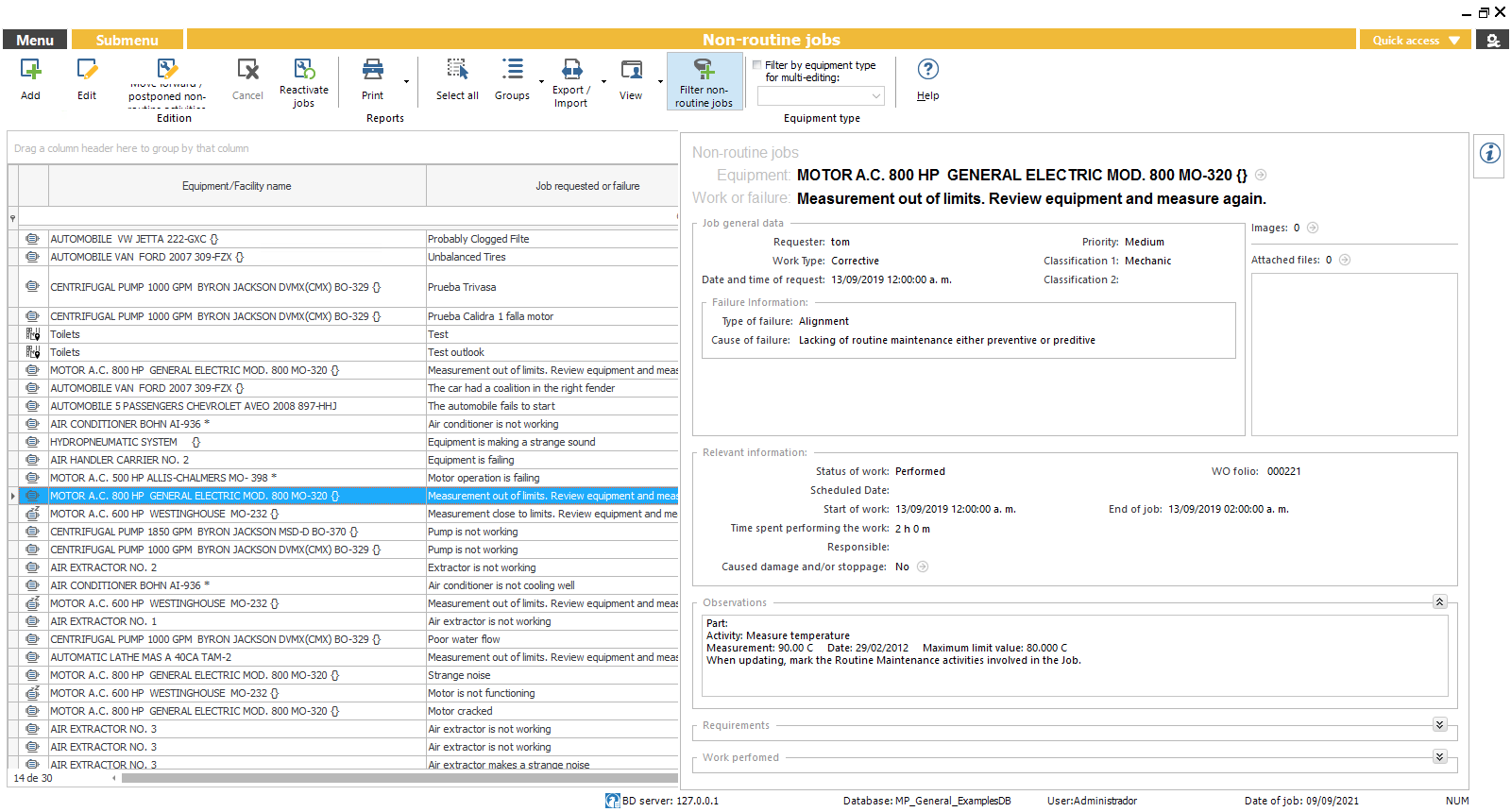

Alert about equipment with measurements outside or close to limits

There are maintenance jobs that involve taking a measurement, such as measuring temperature, vibration, etc. Document in the MP the value of the measurements you make to your equipments.

The MP graphs these measurements and keeps you informed about all those equipment with measurements outside or close to limits.

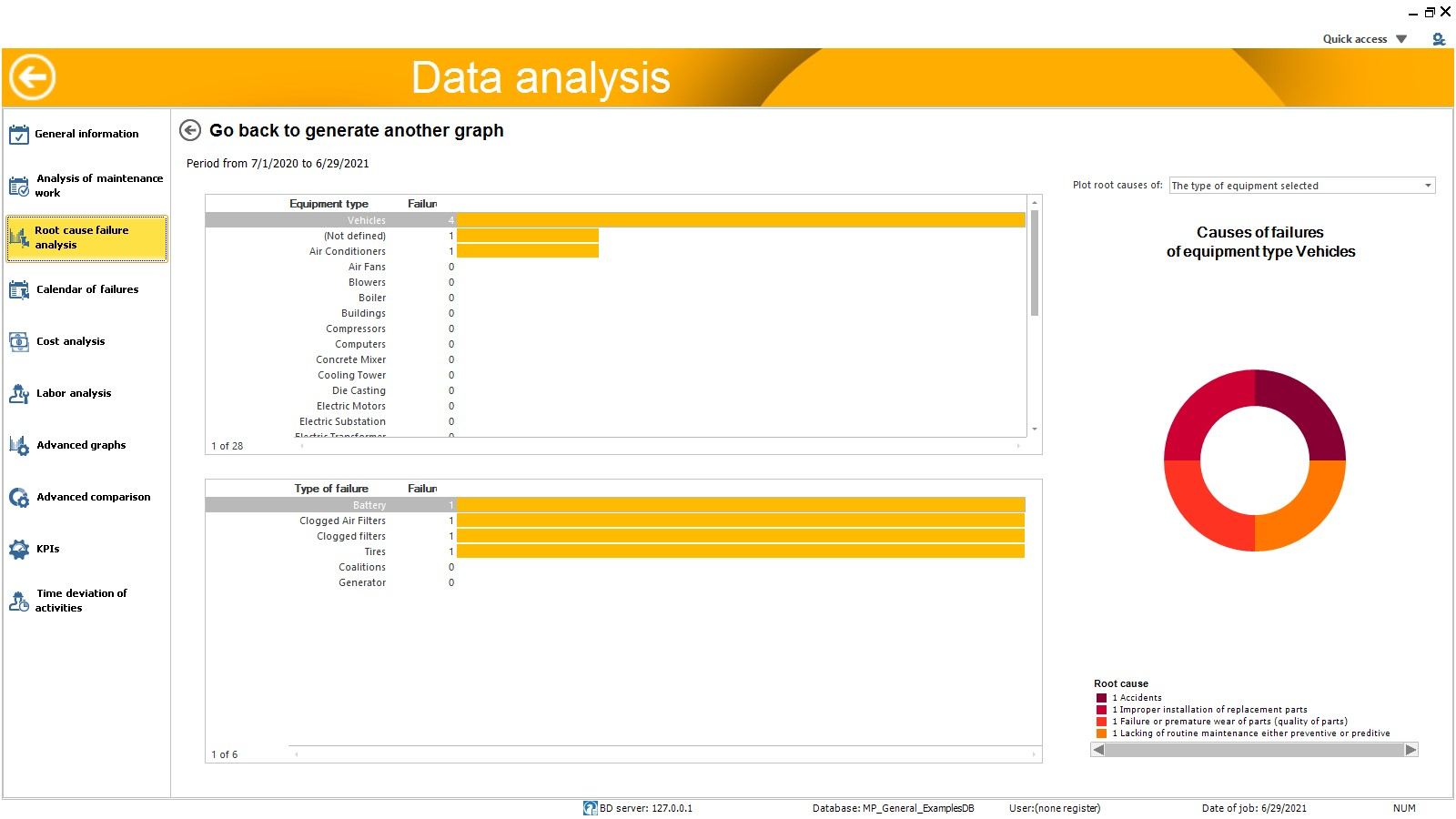

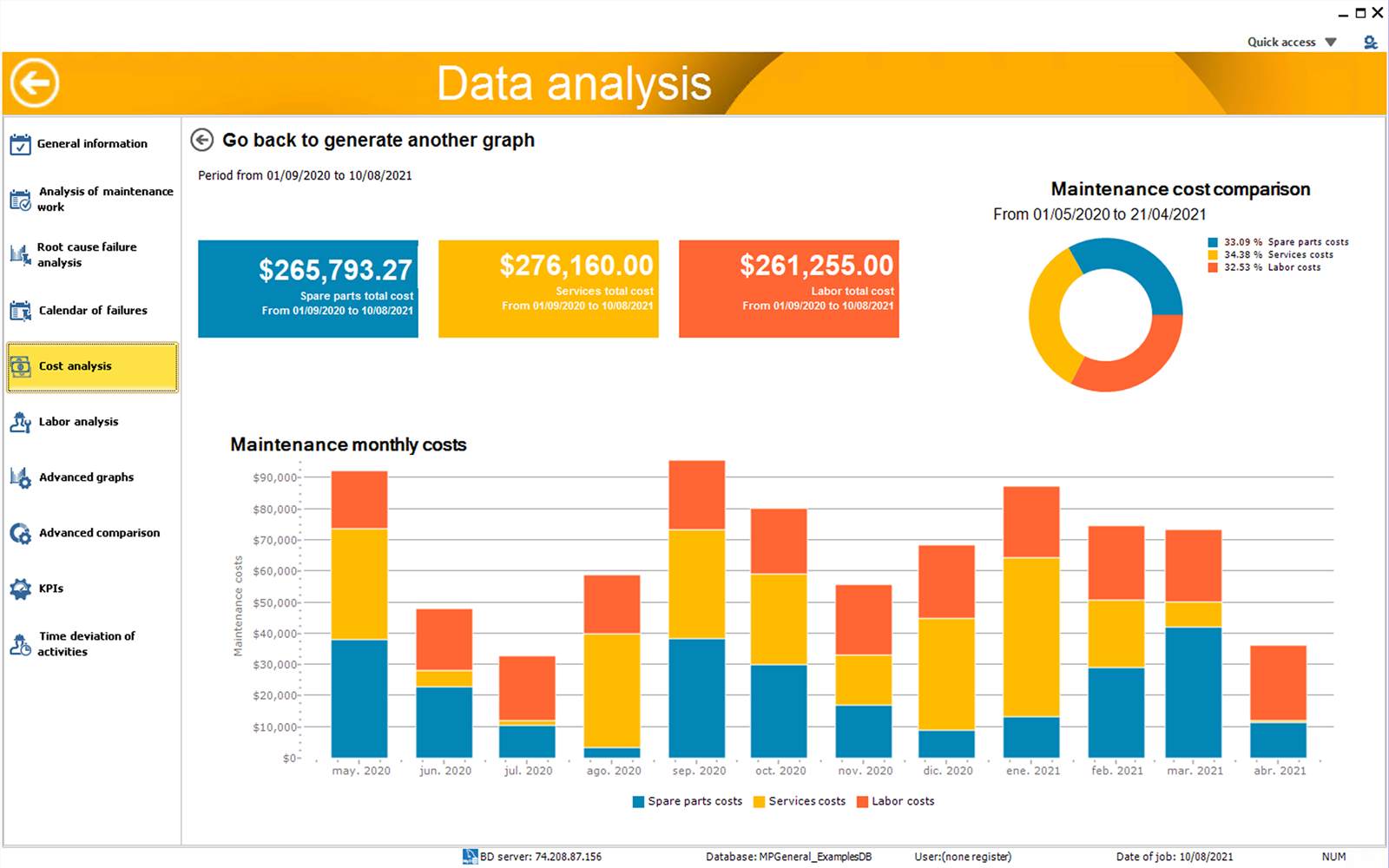

KPI’s and maintenance indices

KPIs are maintenance indicators that help you quickly obtain an overview of the status of your maintenance management at the time of your inquiry.

For example, number of open work orders, number of overdue activities, number of equipment out of service, etc.

The MP calculates three maintenance indices (Mean Time Between Failures, Mean Time to Repair and Availability)

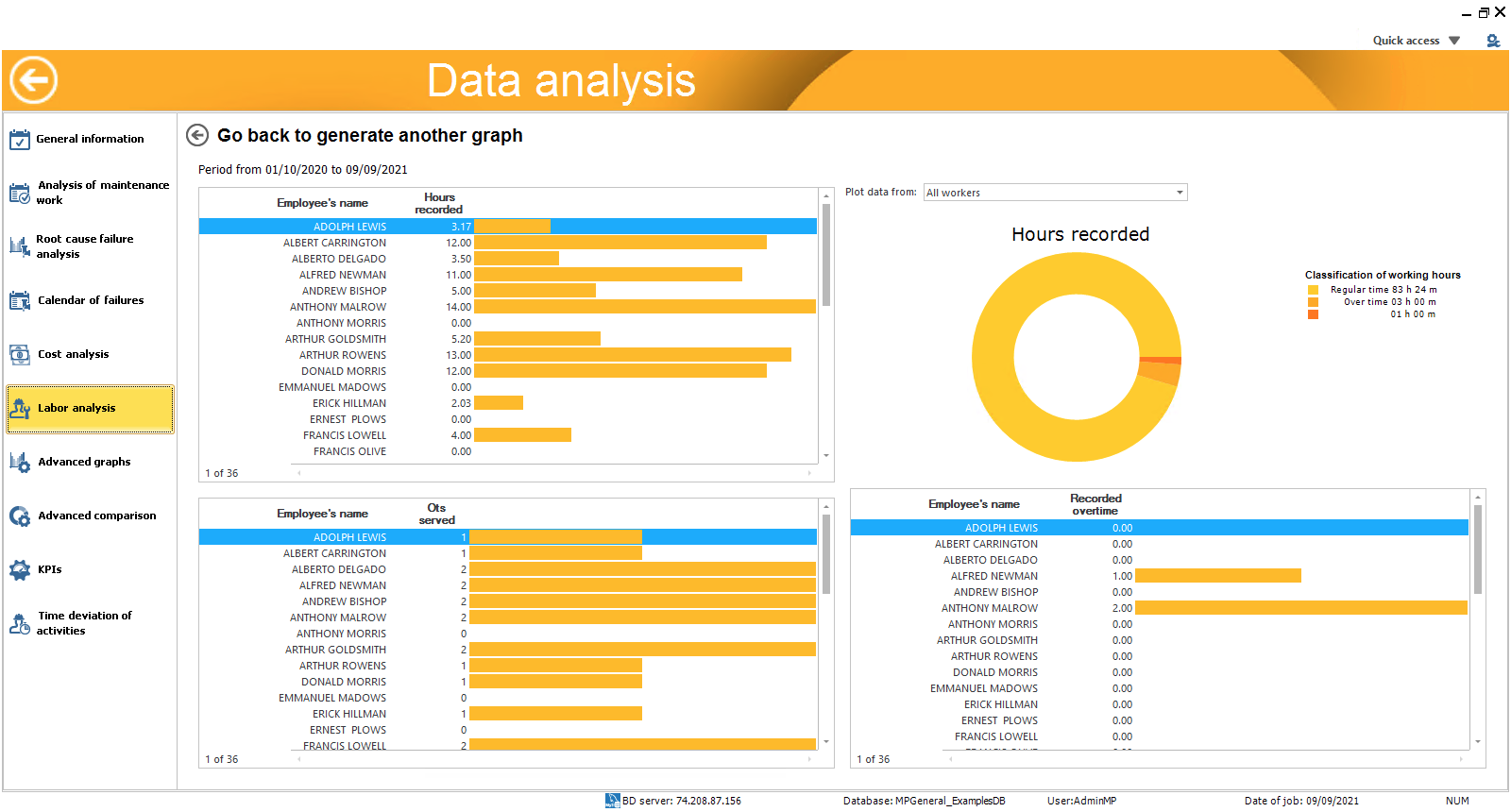

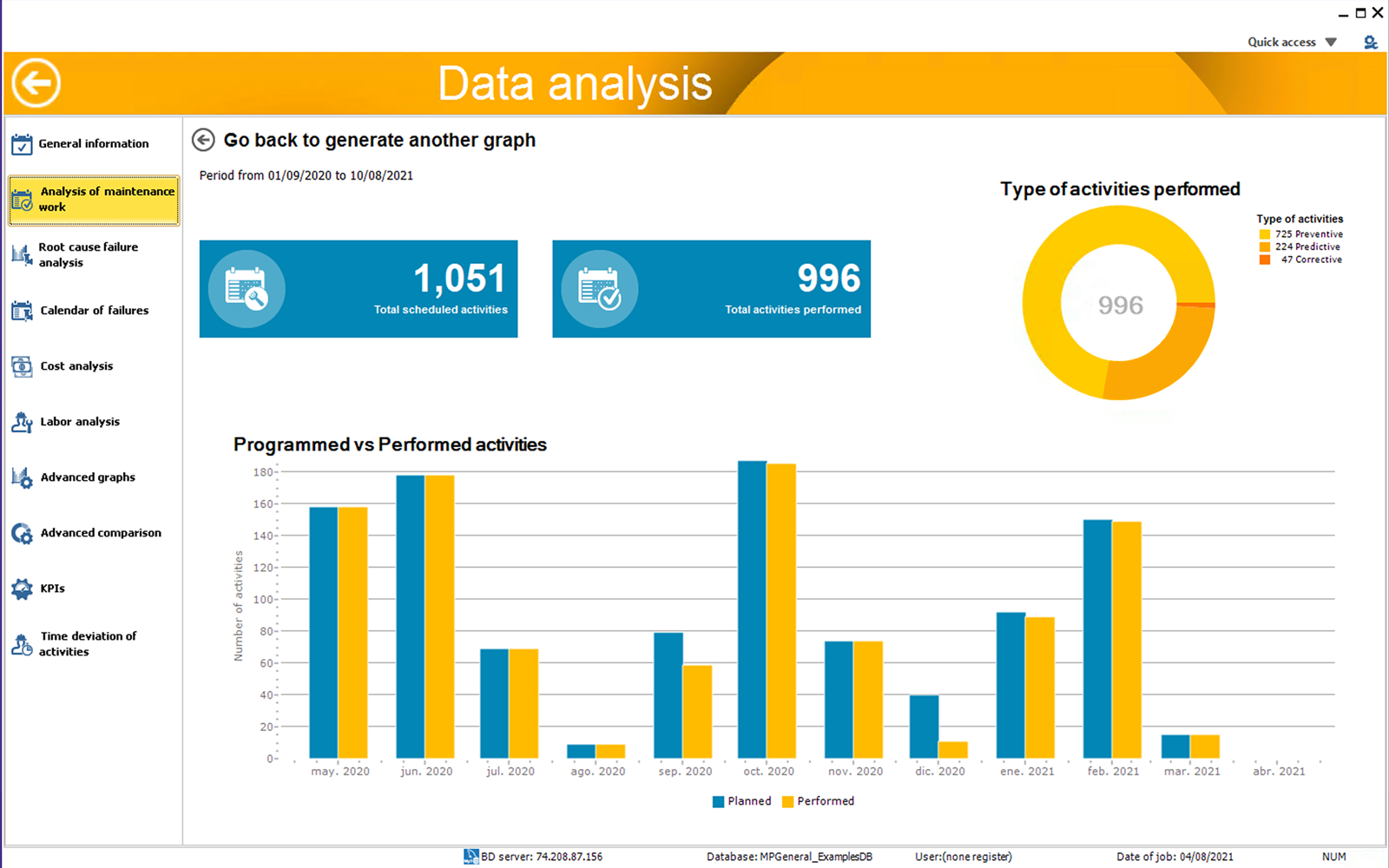

Analysis of scheduled activities vs activities carried out

Graph in which the number of scheduled activities and the number of activities performed are compared monthly .Version 10 presents a new dashboard with a series of pre-designed graphics and relevant information regarding the number of activities carried out and scheduled activities, the type of activities carried out, etc.

A powerful and professional CMMS with great functionality makes the difference

Menu and submenu

We have improved the browsing experience with the new menu and submenu that make MP version 10 a much more intuitive and easy to operate program compared to previous versions.

Advanced Filter function

When you handle large volumes of information, having advanced filter tools is a very important added value in your maintenance management.

Search by content in the list of work orders, whether you want to find a team, an activity, a part of a team, a classification, priority, etc.

Configurable information meshes

The versatility of the MP also allows you to configure the view of the information meshes, adding or removing columns, moving them in position or adjusting their width.

Information panel

An extremely useful drop-down information panel is incorporated in version 10 to quickly consult and have at hand all the information of the selected equipment or registry.

Multiple editing tool

The Edit Selection or Multiple Edition tool allows you to modify the information of several records in the mesh, thus achieving a much faster and easier editing of a list, compared to individual editing.

Grouping mesh information

The Group function allows grouping the content of the information grid, giving great flexibility to organize the information that the user sees on the screen.

If you are already a user, download it right now!

*Do you want to be a user? We highly recommend attending a free online demonstration for software best practices. Schedule Now

MPsoftware helps you meet the standards for ISO certification.