The CMMS MP informs you daily about the maintenance work that must be done and when they’re done. The CMMS reschedules the next dates the maintenance tasks must be completed.

CMMS

Maintenance Planning and Scheduling Software

Simplify the creation, control and monitoring of work orders

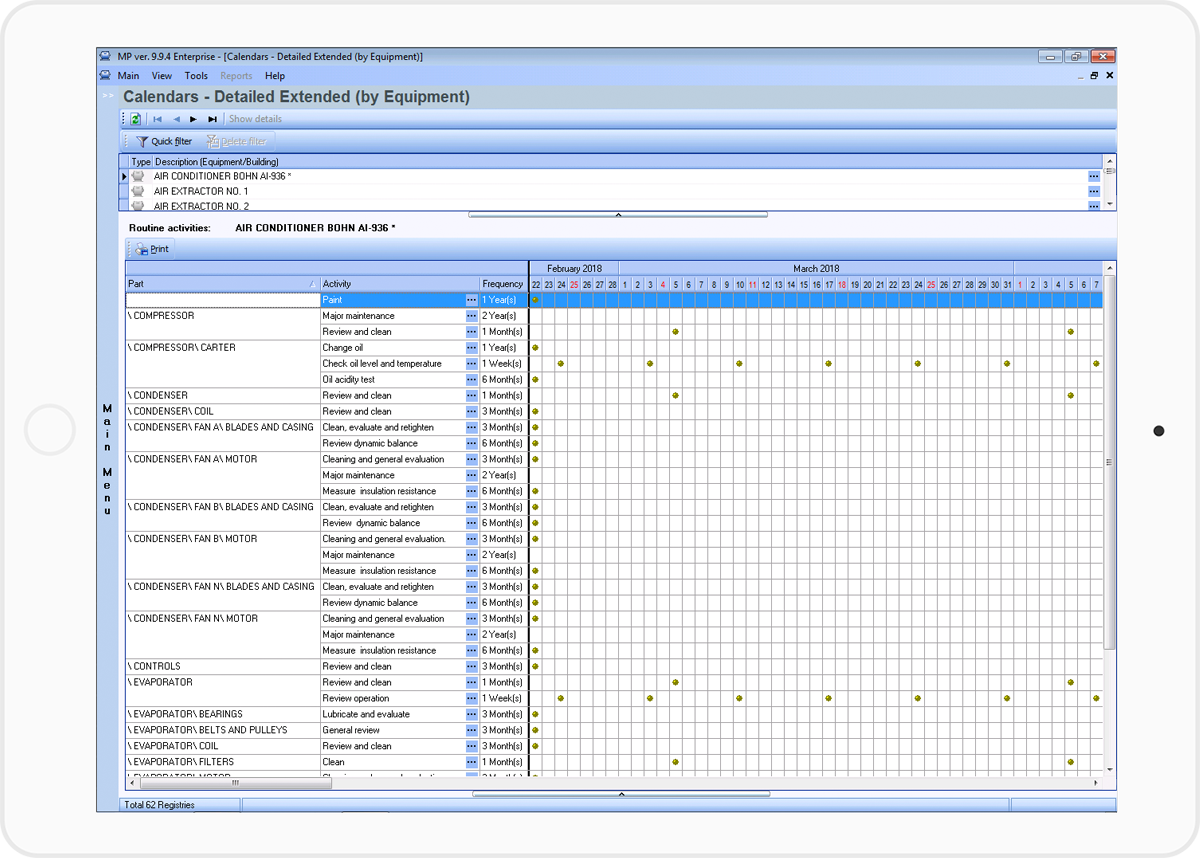

The CMMS automatically generates maintenance calendars

In the maintenance calendars, the CMMS MP marks the dates when the different maintenance tasks must be carried out. The MP is responsible for keeping these calendars updated.

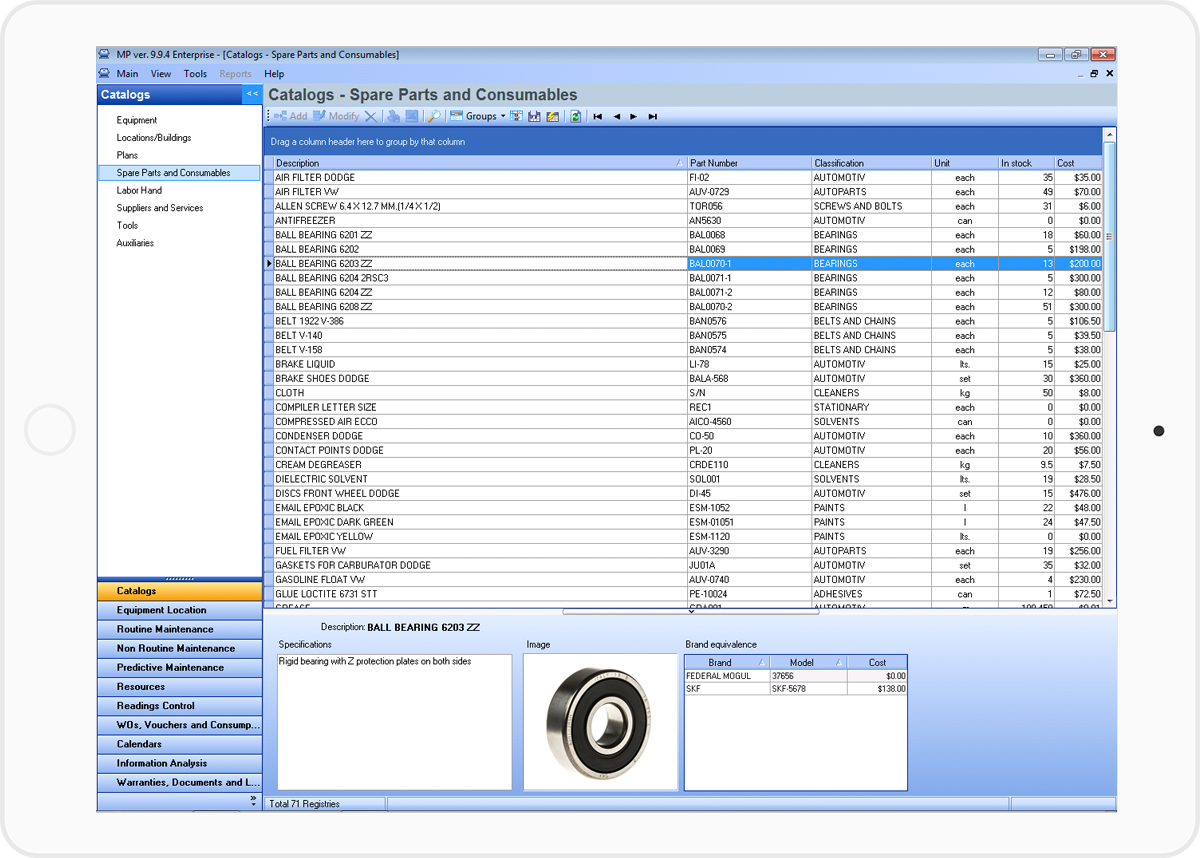

Control your Spare Parts Inventory efficiently with this CMMS

The Spare Parts Inventory is connected with the CMMS MP to automatically and timely calculate the supply of the spare parts and consumables that must be purchased to comply with the maintenance programs.

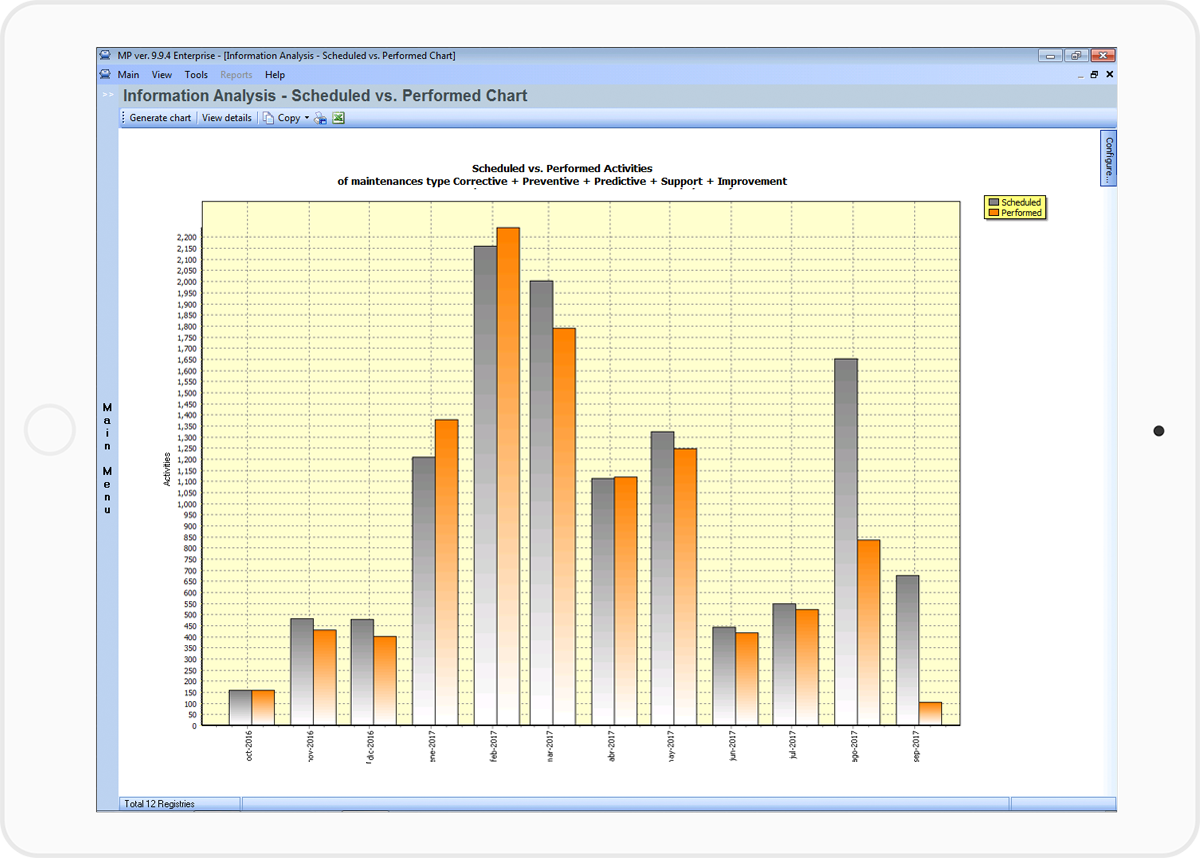

MPsoftware generates a large number of reports, indexes and charts related to maintenance management.

A CMMS thought in ALL maintenance needs.

Equipment catalog

Complete your equipment catalog and document it all in the CMMS Software. All your equipment information; such as images, location, plans, attachments, specifications, notes, guarantees, supplier data, etc.

The MP allows great versatility by allowing the user to set their own custom fields in order to capture the equipment catalog.

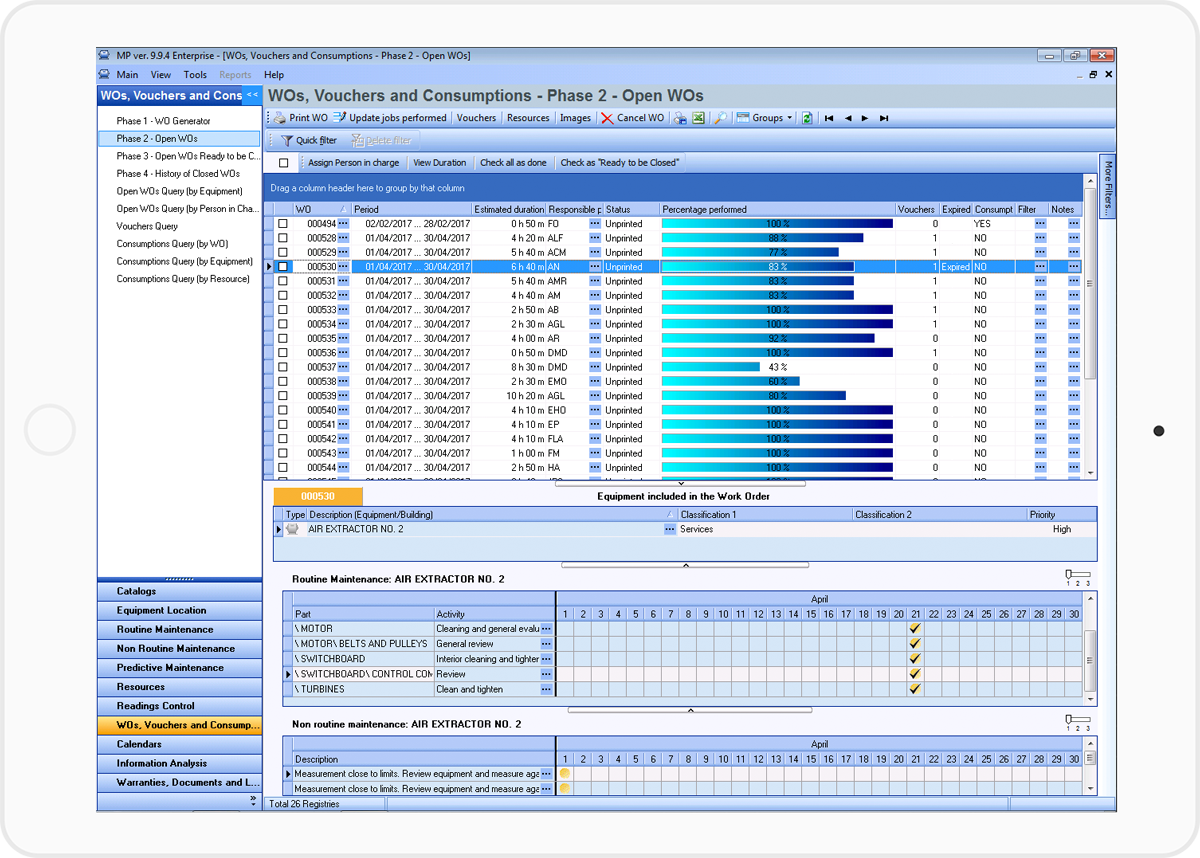

Work Orders

Day by day the MP analyzes the dates of scheduled jobs and reports on the work to be performed during the period. Select jobs and generate work orders automatically from the CMMS MP. For each work order that the user generates, the MP assigns a consecutive folio number for its control. In the same work order, several jobs can be optionally included, both routine maintenance and non-routine maintenance. It is also possible to optionally include one or several computers or locations in the same work order.

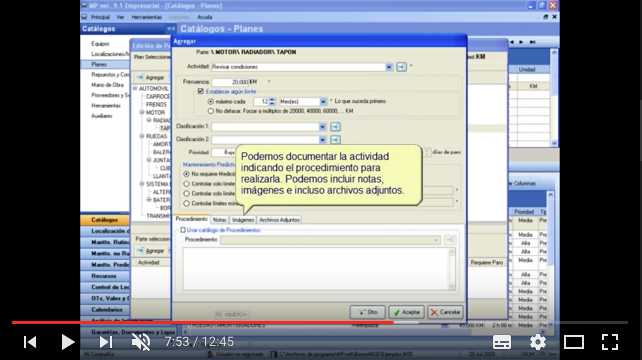

Maintenance routines

Document your routine maintenance plans for equipments and locations; indicating the routine activities that must be performed, their frequency that each activity must be performed. The MP allows you to establish maintenance plans based on time or readings such as kilometers traveled, hours of use, etc. It is even possible to establish plans combinning dates and readings, whichever comes first.

Automatic calculation of maintenance schedules

In the maintenance calendars, the CMMS MP marks the dates when the different maintenance works must be executed. The MP is responsible for keeping these calendars updated. Due to the amount of activities that must be controlled and the fact that the calendars are constantly updated, this is only possible with a computerized system such as the MP.

Spare parts and consumables inventories

The Professional MP and the Business MP include a very complete inventory program called Spare Parts Inventory. This allows to efficiently control stock of materials and spare parts, movements of inputs and outputs, kardex, valuation of inventory by different methods, calculate the supply, suppliers , purchases, etc. Another feature is the option to manage multi-stores and equivalent brands for the same product, as well as barcodes. Although the inventory is an independent program to the CMMS MP, from the MP, the user can connect to the database of the Inventory to check stocks, automatically generate the output vouchers of material, determine the spare parts and consumables necessary to carry out the different activities.

Work completion update

Once the work is done, the user must report it to the MP. When the user reports the tasks completion. The MP automatically generates the next date the task must be carried out again. As the tasks are marked as done, a graphic control shows the progress of each OT and the next date of completion.

Supplier catalogs and external services

The MP includes a catalog of equipment and service providers. The equipment that is registered in the MP may interact with their respective providers. The user will be able to consult the provider’s information online, such as contacts, telephone numbers, etc. You can also create a catalog of the services that each provider offers and document it in the MP service consumption.

Resource flow

The maintenance software calculates the amounts of each resource to be used in the following days or months, as well as the programmed costs; this is done by knowing the resources required to perform each activity and the dates scheduled to perform them.

Automatic supply calculation

The Spare Parts Inventory consults the MP to timely calculate the supply of spare parts and consumables that must be purchased to comply with the maintenance software. The calculation is performed taking into account stocks and programmed resources.

Workload distribution

The MP has tools that will help you distribute work orders among maintenance personnel according to the specialty and estimated duration of each order.

Maintenance indexes

The MP calculates three maintenances indexes (Average Time between Failures, Average Time for Repair and Availability)

Analysis of failures and root causes

Detect the equipments that have the most failures, the most frequent crashdowns and their causes.

Cost graphs, stoppages, etc.

This graph compares the amount of programmed activities and the number of activities carried out every monthly.

Locations catalog

Structure in the CMMS the tree of locations that will allow you to document the location of each and every one of your teams. Thanks to the tree structure of the catalog of locations, you can set filters to locate the equipment at any level of the tree.

Applications via internet

Report maintenance requests via the Internet. Maintenance requests that are reported through the Internet go directly to the maintenance personnel. Each time someone reports a maintenance request via Internet, a window opens on the maintenance managers’ screen displaying the tasks, reports or requests reported by the staff. On the other hand, people who make a request can check the status of your application.

Predictive measurements

There are maintenance jobs that involve taking measurements such as: temperature, vibration, wear, etc. Document in the CMMS Software the value of the measurements you make to your equipment. The MP graphs these measurements and keeps you informed if all the equipment measurements are outside or close to limits.

Labor catalog

In the MP, the user captures the Manpower Catalog in which the names, specialties, hourly costs and extraordinary costs of the personnel involved in the maintenance tasks are recorded. The information in this catalog will allow the designation of responsibles for each work order, as well as the time taken by each labor to complete these.

Safeguards control and tools returns

The Professional MP and the Business MP include a program called Tool Control. This program allows to control safeguards and returns of all the tools given to the workers. The program allows, among other things, the online consulting of who has or where each of the tools are located. Before proceeding to carry out the maintenance work, the user can consult the availability or stock in the warehouse of the tools he will use to carry out the entrusted tasks.

Warehouse vouchers

Generate warehouse vouchers automatically in the MP. Download them when generating your exit movement from the spare parts inventory.

Resource Association and activities

The association of resources to activities is to establish for each routine maintenance activities, material resources (spare parts and consumables), labor, outside services and tools needed to perform them.

Consumption

The MP allows you to document the consumption of spare parts, workforce and external services used during the execution of maintenance works. This will allow us to make inquiries about the resources used in each team and to analyze maintenance costs.

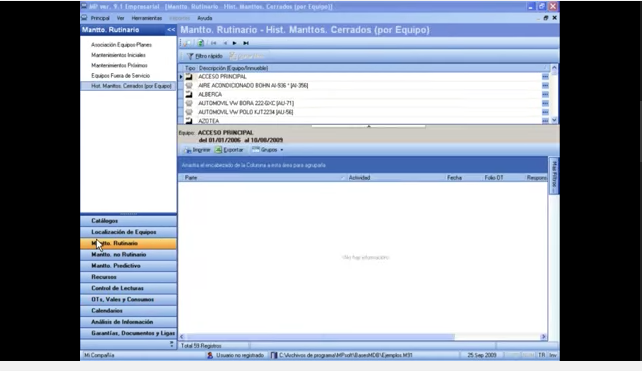

Consumptions and executed tasks records

The CMMS MP keeps organized, up-to-date and makes available for consultation all the historical information referring to accomplished tasks and resources used.

Guarantees’ control

The MP allows you to document the guarantees of each equipment. Whether it’s the equipment warranty, a spare part or even a service guarantee. By accessing this module you can consult all the valid equipment guarantees.

Graphic records

The MP graphically shows the records of maintenance performed on an equipment in a period of time, showing protected periods and unprotected periods. This graph is an indicator to assess the vulnerability of the equipment. It is possible to visualize how closely the scheduled maintenance has been carried out. It also allows to relate failures with the maintenance plans helping to make the necessary adjustments in the maintenance plans to avoid that certain failure reappears.

Security

For the safety of your system maintenance, the MP allows to register users who have access to the program. Registered users will have access to the MP through an access code and may have full or limited permission to access the different modules and execute certain functions.

Scheduled VS performed graphic

This graph shows the amount of programmed activities and the number of activities carried out every monthly versus previous months.

Library

A library is a file that contains a series of prefabricated maintenance plans of various equipments. The MP includes libraries of a wide variety of prefabricated maintenance plans that will undoubtedly make the implementation of the MP much easier.

MP Maintenance software demo videos

Equipment and Locations Catalogs

This video demonstrates all aspects related to equipment catalogue.

Routine Maintenance Schedule

The video demonstrates what a routine maintenance plan and how is it structure in the CMMS MP.

Maintenance Calendars

Once user defined plans or routine maintenance, maintenance schedules in the CMMS MP mark the dates when they performed various maintenance work, taking care to keep up to date and these calendars.

Upgrade, Administration and Closing Work Orders

The video shows everything about the upgrade, administration and closing of the work orders, and query of the job history performed .

MPsoftware offers the widest range of connectivity options

From a single-user installation to the most complex enterprise network

MPcloud

As an option we offer the hosting service of the MP in the cloud. This allows you to access your information from anywhere you are, with any device with Internet access and without the need of any IT infrastructure.

Send maintenance requests to the MP from your mobile phone

MPmobile is the app that lets you send maintenance requests instantly to the MP program manager from your mobile device.